Performes Test of Photovoltaic Systems

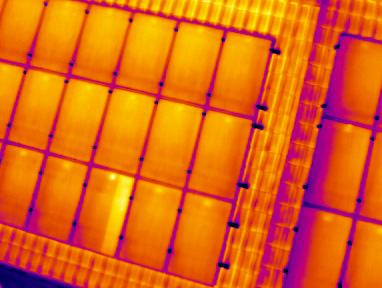

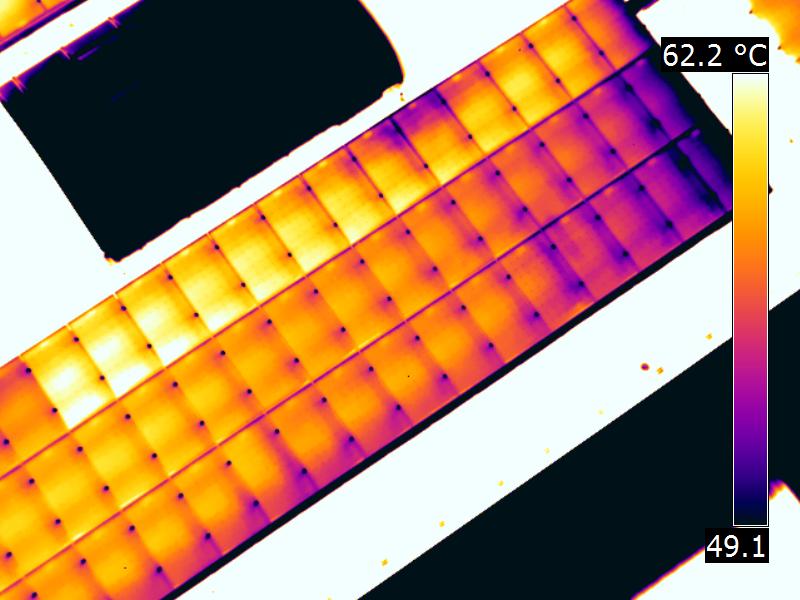

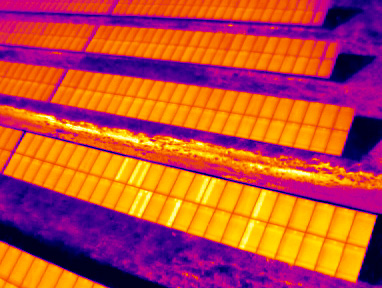

The detection of faults on the PV Systems with the thermography drones has been proven in practice. The flying robots are equipped with high-resolution (640 x 480 pixels) infrared cameras. We have been detecting and recording faults and damages on PV Systems since 2011. Damaged or defective solar cells (hot spots- localized solar cell defects) have higher or lower than average temperatures. Faulty solar panels are detected and further abnormalities are identified on the PV systems by means of non-contact infrared measurement. The evaluation of the generated infrared images is an essential part of the whole process. Depending on the contract, the evaluation is prepared on the basis of a radiometric video or an image. A comprehensive thermographic evaluation provides corrective recommendations. A thermography drone survey is performed during normal operation of the solar system. On the basis of our work and experience we provide support for the optimization of PV systems, assist in the enforcement of warranty claims and the recovery of profit losses from the insurance companies. Photovoltaic systems thermography from the air using drones is fast and cost-effective. The cost will depend upon the size of the system in kWp (kilowatt peak) and the scope of the inspection. It is possible to get an overview of the condition of PV modules of a 6-8 MW solar farm in just 3 to 4 hours. More detailed information may be obtained from the User Report of FLIR™ - market leader in the infrared technology. Other survey methods, such as electroluminescence (EL) measurements, are also part of our services. We are happy to advise you on the application of photovoltaic thermography.

Detection of faults on PV systems

We perform comprehensive thermographic surveys of photovoltaic systems. Our thermography drones, which are equipped with high-resolution infrared cameras (FLIR T620 or Optris PI 640) provide for fast and reliable inspection of PV systems to detect malfunctions or defects. Ensuring optimum efficiency, especially against the background of falling feed-in tariff is thus secured. Owing to a special technology, we can do without helicopter sky lifts or helicopters, and make use of the zero-emission properties of our flight facility to contribute to the environment. Additional Services: optimisation of solar systems, plausibility check of solar electricity profits, preparation of reports, annual audit and studies for the restoration of the photovoltaic systems. We will be happy to develop for you a tailor-made proposal. With our extensive range of services for troubleshooting and optimization of PV systems, we provide support to private solar system operators, consultants, contractors, operating companies, operators, buyers and sellers. Optimize your investments with our expertise.

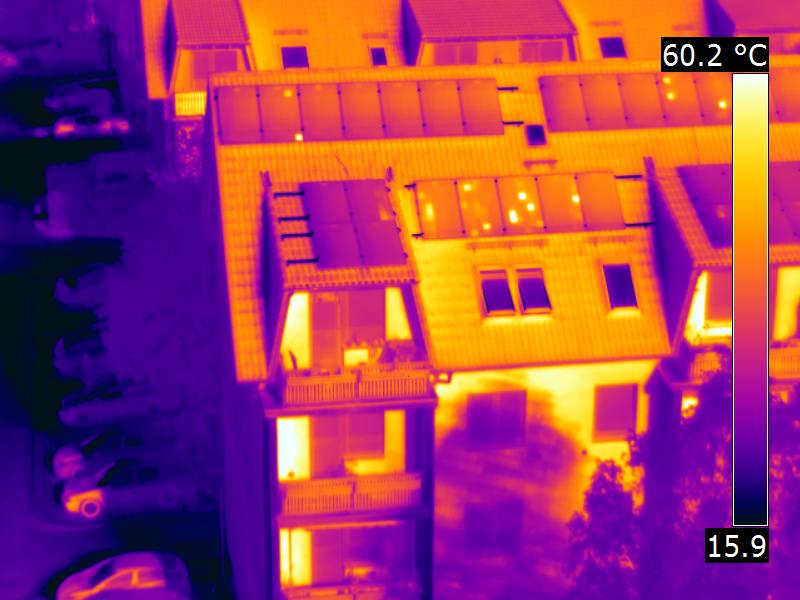

Inspection of photovoltaic roof systems

In addition to the fault analysis on solar farms, the detection of defects with the thermography multicopter could also be used for PV rooftop installations. The advantage of the flying robots is their ability to operate from any angle or height. In particular, the right angle (ideally 90°) is important for the survey. Furthermore, high-priced sites (time and material) of lifting platforms thus remains spared. It takes only a few minutes to bring a thermography copter into operational availability to inspect PV systems within a short time, whether it is a 10 kWp or a 1 MWp PV rooftop installation.

Detection of Defects on PV Systems - Price

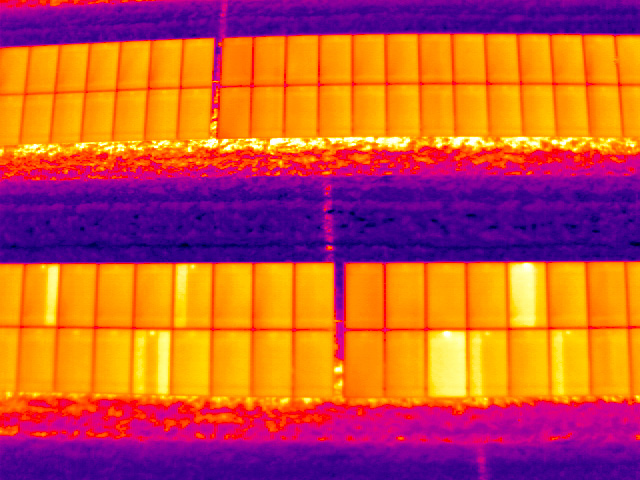

Indentifivation of defects and faults on PV systems using thermography

- Diode-function check (defective bypass diodes)

- Identification and location of heated cells and formation of hotspots

- Module failure (including partial failure)

- Faulty installation, including other faults, such as cabling, etc.

- Moisture, penetrated from the outside

- De-energization, cracks and mechanical breakage, etc.

Infrared images with errors on PV modules

Thermographic Evaluation

A survey report is prepared according to the customer requirements. The faults on the photovoltaic systems, which are important for the Customer, are documented. In the event of the evaluation of the thermographic survey, an agreement is reached with the Customer in advance, so that they know exactly what they get as a result of the survey and could assess the expenses, associated with the survey. The links show two examples of thermal images/survey reports:

Thermal Image 1 Thermal Image 2

One of our missions is documented in the uesa GmbH with a short video. Detection of Faults on Solar Power Plants with a Flying Robot

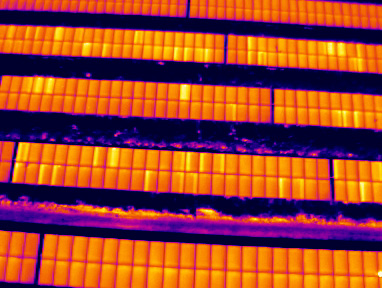

Further Development of Photovoltaic Thermography

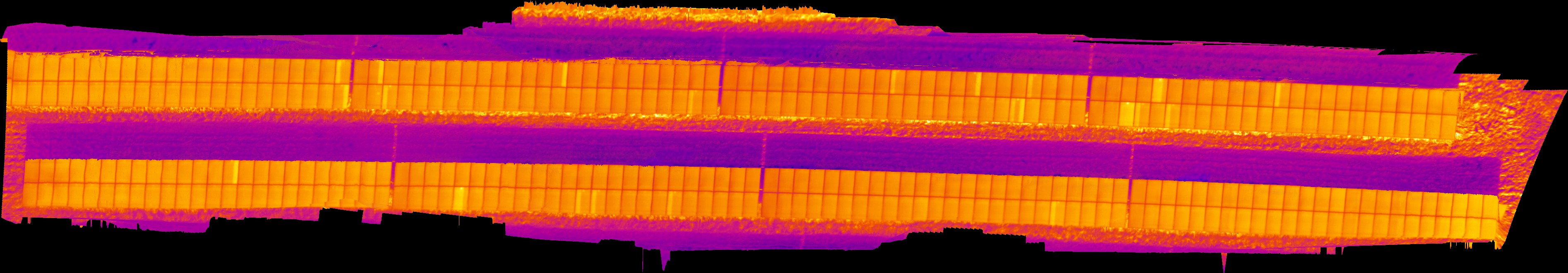

Currently we are working with the survey engineers on the technology for the development of the automated fault detection. The aim of this technology is to obtain an orthophoto based on the string plan. The orthophoto must facilitate and significantly accelerate the survey after the flight. The multicopter provides for the possibility to plan and to save the fight routes according to the GPS coordinates. The UAV (unmanned aerial vehicle) can use these data for an autonomous inspection flight around a solar farm to generate radiometric data. In the process of evaluation the infrared images are combined with the orthophoto. This procedure provides for fast identification of defective PV modules. This method is intended to reduce the costs and offer the opportunity for the inspection of photovoltaic systems at regular intervals and optimize the production. Now we have implemented the theory into practice and, as the first result, we have created an orthophoto from infrared images, which contains eight tables with 384 PV modules. A stream from Optris PI 640 radiometric thermal imaging camera was the basis for this IR image. A true ortho-image size is 3789 x 660 pixels.